STC Spinnzwirn GmbH

Booth number: D57

www.stc-spinnzwirn.com

About us

“Demanding applications require the best equipment.”

STC Spinnzwirn supplies high-tech textile machinery and equipment from Chemnitz all over the world. Founded in 1866, the company with its two business segments is a leading manufacturer of complete solutions and single components for the extrusion of monofilaments and slit film tapes as well as high-speed winders and accessories for man-made fiber spinning plants.

STC Spinnzwirn´s sophisticated technology in combination with its innovative employees enables customers to produce at the highest quality level.

Address

Zwickauer Str. 247

09127 Chemnitz

Germany

E-mail: info@stc-spinnzwirn.com

Phone: +49 371 23880

Internet: www.stc-spinnzwirn.com

Contact person:

Harald Müller

Regional Sales Director

E-mail: harald.mueller@stc-spinnzwirn.com

Mohamed Mahmoud

Regional Sales Director

E-mail: mohamed.mahmoud@stc-spinnzwirn.com

Products & Services

Monofilament

Monofilament yarns are used for Artificial Grass for Sports and Landscape, for Agricultural Textiles such as shade fabrics, for Geotextiles such as fabrics for road construction, for concrete reinforcement and several special applications.

As a solutions provider, our portfolio includes not only the extrusion line, but also downstream equipment such as texturing, wrapping and twisting.

Using our machines and equipment you will convince your customers with high yarn tenacity, low maintenance costs, high efficiency as well as even and high yarn quality.

Tape

Boost operations with extreme productivity. And create room for new ideas.

Achieve superlative efficiency with the lowest energy consumption, raw materials usage and staff requirements. And create capacities for new projects.

Ensure your production is sustainable, efficient and future-oriented. And make your systems profitable – for many years to come!

Filament

Our winders are running at manufacturers of yarns for airbags, tire cord, truck tarpaulins, belts, ropes and much more since more than 25 years. We have customers in Germany and Europe, Asia, North, Central & South America and Africa.

Our customers benefit from decades of experience in winding perfect bobbins to meet the continuously growing requirements for weaving, cabling, twisting and tufting machines.

This reflects in higher sales prices of their bobbins and higher margins of the final products.

We offer two highly proven traverse systems - cam shaft and cam shaft in combination with a groove roll.

It is not the yarn but the grooved roll decides how we place the yarn exactly on the bobbin.

The high-speed winders of our product portfolio cover a speed range of 800 up to 5,000 m/min. The 600 and 1,200 mm long chucks can be used to wind up to 8 yarn ends per winder.

HIGH-SPEED WINDERS FOR POY - FDY - IDY

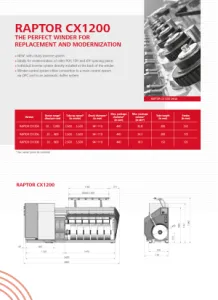

RAPTOR CX1200

THE PERFECT WINDER FOR REPLACEMENT AND MODERNIZATION

» NEW: with rotary traverse system

» NEW: up to 12 yarn ends on 1500 mm chuck

» Individual inverter system directly installed at the back of the winder

» Winder control system offers connection to a main control system via OPC and to an automatic doffer system

RAPTOR CX1500

THE PERFECT WINDER FOR NEW SPINNING LINES

» NEW: with rotary traverse system

» NEW: up to 12 yarn ends on 1500 mm chuck

» Individual inverter system directly installed at the back of the winder

» Winder control system offers connection to a main control system via OPC and to an automatic doffer system

Carpet Backing

THREE PRODUCTS - ONE SOLUTION TO

PRODUCE TAPE YARN FOR CARPET BACKING

EFFICIENTLY AND FUTURE-ORIENTED

» Warp and weft for primary backing and woven carpets as well as warp for secondary backing

» High and continuous production speed up to 400 m/min*

» Identical tape properties and almost no waste during production due to the combination of EvoTape and WinTape

» EvoTape available with different extruder dimensions and different working widths from 800 up to 1,600 mm to reach an output of nearly 750 kg/hour

Artificial Grass

FOR THE COMPLETE PRODUCTION OF ARTIFICIAL GRASS YARNS

FOR ALL KINDS OF APPLICATION FOR SPORTS AND LANDSCAPING

» MaryLine available with different extruder dimensions and working widths to reach the required output of mono- or bi-color yarn

» Sustainable production of BiComponent monofilaments

» Tape production for high process and cost efficiency

» Downstream equipment for texturing and/or wrapping as well as twisting available

DD2000 - TWISTING OF MULTIFILAMENT YARN

» Twisting flyer for processing of plied supply bobbins and to avoid filament breaks

» Bobbin formation with precision winding for an increased downstream process speed

» Meter counting for equal bobbin length

» Individual control of all twisting positions to have the necessary flexibility

MAR.CX __ TAKE-UP MACHINE FILAMENT YARN

TWO PROCESSES – ONE MACHINE ARRANGEMENT

INCLUDING HEATED GODETS AND WINDER TO PRODUCE FDY AND IDY

MAR.CX – THE (R)EVOLUTION OF TAKE-UP FOR FILAMENT YARN

» Most compact design and small footprint

» Ideally for low building heights

» Suitable for modernization of existing spinning plants

» Flexible arrangement with up to 6 heated duos

» Available with all our high-speed winders

» Modular structure – easy commissioning

-thumb.webp)

-thumb.webp)

-thumb.webp)

-thumb.webp)

-thumb.webp)

-thumb.webp)